Material consistency is not only important for quality in industrial manufacturing; it also impacts the performance of goods, how efficiently the process runs and how satisfied customers are. Pug mills are especially noted for their ability to mix, blend and homogenize materials with great accuracy. For the chemical, construction, pharmaceutical, ceramic or paint industries, pug mills provide a consistent approach to getting a uniform material batch after batch.

What the Pug Mill Does

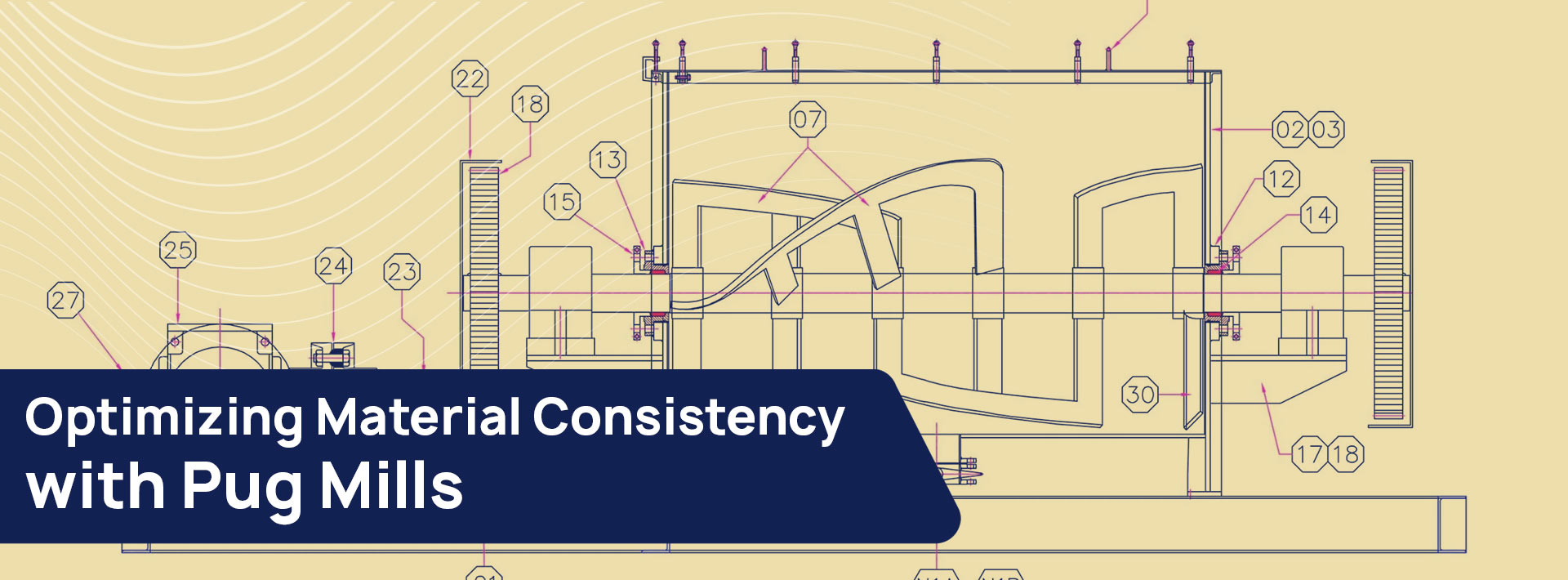

Essentially, a pug mill is a machine that blends materials using mechanical agitation. Almost always made with twin counter-rotating shafts featuring paddles or plows, the mixer ensures everything is blended into a single mixture.

They work best when they are used for:

- A variety of dry and wet materials have to be mixed.

- It’s important to break down any clumps that form.

- A liquid should be spread evenly over the base of a solid.

- Production of large quantities requires constant and rapid mixing.

You May Also Like: Understanding the Basics of Pug Mill for Industries

Why It’s Important to Keep Material Consistency

Having materials that aren’t consistent in their makeup can create many problems in industrial processing.

- Products not working properly

- A lot of batches are being rejected, and high waist

- Problems caused by blockages or wear in machines

- Dangers that can occur when chemicals react

- Problems with final processing

By optimizing the mix in a pug mill, all particles or droplets are placed correctly, eliminating weak spots in the formula and resulting in more consistent products.

You May Also Like: Top Features of a Pugmill Mixer for Efficient Mixing

How Pug Mills Obtain Optimum Consistency

Let’s dissect how pug mills live up to their promise of consistency:

Aggressive and Uniform Mixing

Rotating shafts in a pug mill mix the material comprehensively, enabling additives, binders, or liquids to become evenly distributed throughout the bulk mass. Mixing inhibits segregation and produces a homogenous mix, which is particularly important in chemical processing and paint manufacture, where small variations can change product performance.

Controlled Liquid Addition

Pug mills can also be equipped with spray bars or injection nozzles to introduce controlled amounts of liquids into the mixture. This provides accurate moisture control, which is critical in applications such as cement or ceramics, where water content has a direct influence on texture and curing.

Variable Speed and Torque

Through the use of variable frequency drives (VFDs), manufacturers can adjust mixing intensity according to material type without overmixing or undermixing. The outcome is uniform texture and quality in every batch, independent of input conditions.

High Throughput with Minimal Downtime

Pug mills provide continuous mixing, perfect for high-demand production lines. They offer the same consistency from the first to the last kilogram, without lengthy pauses for reloading or manual involvement.

Less Operator Dependence

Once installed, a pug mill can operate with little human involvement. Through automation, the variability introduced by manual mixing operations is reduced and provides consistency in quality for every batch.

You May Also Like: How Pug Mill Mixer Used in Asphalt Plants

Industries Benefiting from Consistent Mixing with Pug Mills

Chemical Industry: Homogenizing pastes, powders, and binders of chemical reactions or formulations.

- Ceramics & Clay: Providing bubble-free, uniform clay with consistent moisture.

- Construction: Mixing stabilized soil, fly ash, and cement to construct roads or to make bricks.

- Paint & Pigment: Uniform blending of color pigments, solvents, and binders to prevent color differences.

- Pharmaceutical: Uniform granule production for tablets and capsules, providing precise dosage.

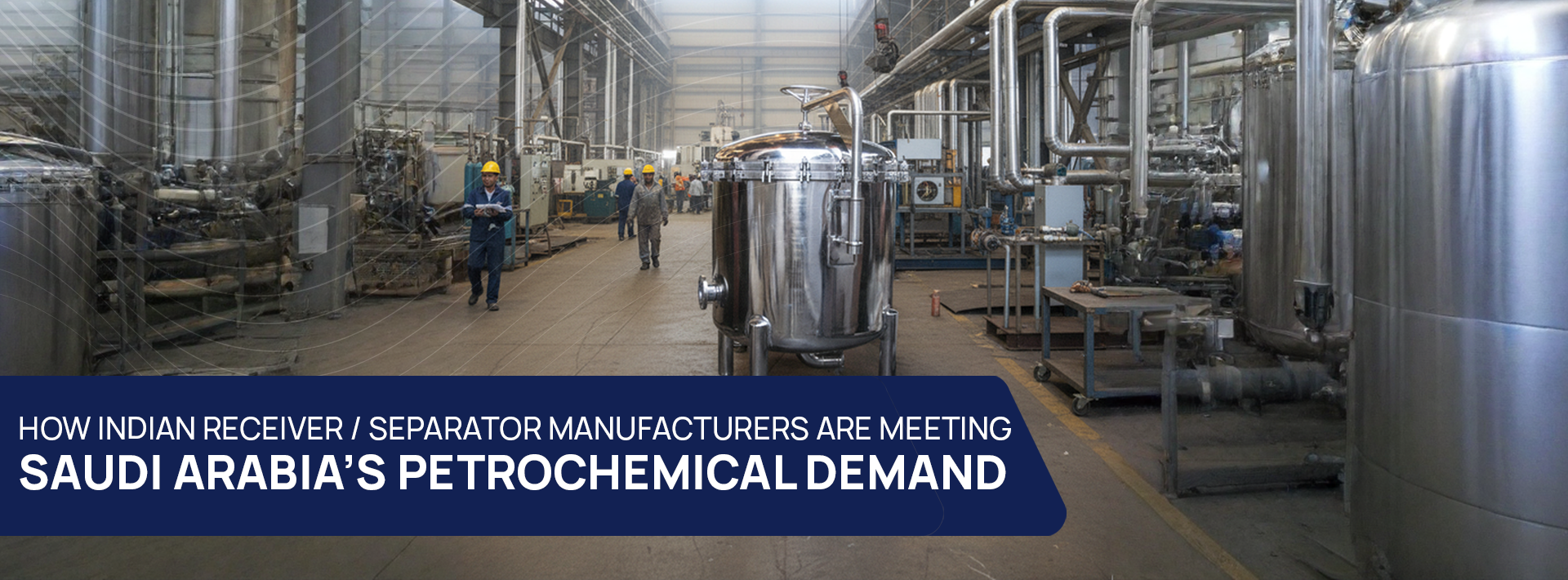

To address increasing demand from overseas markets such as Saudi Arabia, Indian process equipment manufacturers are designing high-precision pug mills according to their capacity to ensure conformity with international quality standards. The equipment is usually incorporated as a component of turnkey solutions in paint and chemical plants to enable manufacturers to provide export-quality material with ISO, GMP, or BRCGS certification.

You May Also Like: Benefits of Pugmill Mixer in Industries

Selecting the Appropriate Pug Mill That Meets Your Requirements

When choosing a pug mill, the most important considerations include:

- Material characteristics (abrasiveness, particle size, viscosity)

- Ideal throughput

- Degree of mixing intensity

- Moisture content control

- Integration with the current processing lines

Top Indian manufacturers provide tailor-made pug mills with corrosion-resistant materials, heating/cooling jackets as optional, and intelligent automation controls for more accurate values.

Achieving consistent results in industry depends largely on the use of Industrial pug mills Manufacturers. Their mixing processes ensure products are well-made, waste is minimized, and customers from around the world are satisfied. If a company wants to improve its production in industries where exports are important, using a well-designed pug mill is both smart and sustainable.

FAQs

1. What is a pug mill used for?

A pug mill is a machine used to mix and prepare materials, most commonly clay, into a homogeneous and workable consistency. It is widely used in industries such as ceramics, pottery, brick manufacturing, and even in road construction where it mixes materials like asphalt or soil with additives.

2. How does a pug machine work?

A pug machine works by using rotating blades or paddles inside a cylindrical chamber to knead and blend materials. The mixing chamber allows the materials to be churned, de-aired (if vacuum-equipped), and extruded in a consistent, uniform mass, making them ready for shaping or molding.

3. How to operate a pug mill?

To operate a pug mill:

- Prepare the materials: Ensure clay or other materials are properly pre-soaked or conditioned.

- Feed the hopper: Place the material into the machine’s hopper.

- Start the machine: Turn on the pug mill, allowing the internal blades to begin mixing.

- Monitor the process: Observe the output to ensure consistency.

- Collect the clay: Once properly mixed, collect the pugged clay from the nozzle or extrusion end.

Always follow manufacturer guidelines and safety instructions during operation.

4. What is the equipment of a pug mill?

Typical equipment or components of a pug mill include:

- Mixing chamber

- Rotating blades or paddles

- Hopper (for feeding material)

- Extrusion nozzle

- Vacuum system (optional, for de-airing)

- Motor and control system

These components work together to blend, compress, and extrude materials in a uniform state.

5. What is a pug mill used for in ceramics?

In ceramics, a pug mill is primarily used to recycle and prepare clay for reuse. It mixes dry and wet clay to achieve the right plasticity and removes air bubbles when equipped with a vacuum system. This process ensures the clay is homogeneous and ready for wheel throwing, hand-building, or casting.

6. Which of the following processes is a pug mill used in?

A pug mill is used in several processes, including:

- Clay preparation in ceramics and pottery

- Brick and tile manufacturing

- Recycling of scrap clay

- Soil stabilization in road construction

- Mixing of fly ash, lime, or other construction materials

Its versatility makes it essential in both artistic and industrial settings.