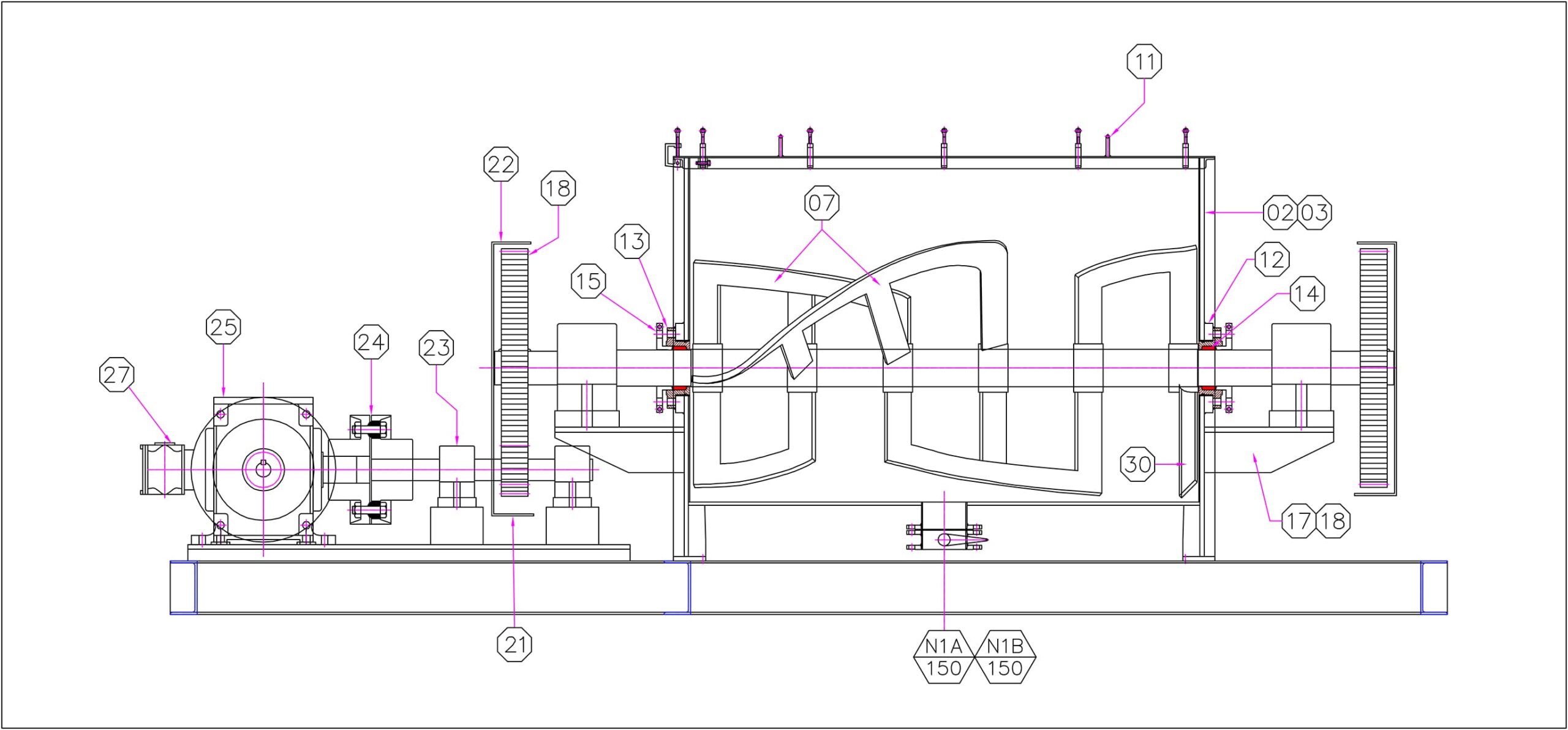

A pug mill mixer, also popularly called paddle mixers are mostly used in industrial settings as mixing devices that are capable of mixing, agglomerating and even conditioning. It finds applications in fields such as pottery, cement, bricks, and parts of the concrete-asphalt mixing process.

A typical industrial pug mill mixer makes use of dual counter-rotating shafts that have pitched paddles to help create the required ‘kneading and folding’ motion inside the mixer. The rotating motion in the pug mill mixer helps lift the material inside up through the centre and then back down to the sides. A pug mill mixer is a fast continuous mixer that produces a homogeneous mixture within the span of a few seconds.

Stalwart International is one of the best pug mill mixer manufacturers, exporter and supplier in India that provides installation and maintenance services.

It is important to take into consideration the various factors of agitation, the drive assembly, the inlet, the discharge, the cost and the maintenance. And hence, a pugmill mixer is the best available option.

Stalwart International is one of the best pug mill mixer manufacturers, exporter and supplier in India that provides installation and maintenance services.

For a road base: A road base requires a dense, well-aggregated, the uniformly mixed and densely compacted mixture for building the foundation for a pavement.

Lime addition to asphalt: An asphalt plant may require the addition of lime to help strengthen the binding property of asphalt, where a pug mill mixer comes into play.

Stalwart International is one of the best ceramic pug mill mixer manufacturers, exporter and supplier in India that provides installation and maintenance services.

Ceramic pug mill for clay body extrusion: A ceramic pugmill mixer is used to extrude the clay bodies before the shaping processes.

Pugmill mixer is used to process both, liquid as well as solid feed and can be employed even for processing of heavy-duty materials.

Stalwart International is one of the best pug mill mixer manufacturers, exporter and supplier in India offering pugmill mixer to varied industries in the country and around. We also provide installation and maintenance services.

Pug mills, also known as paddle mixers or clay mixers, are used primarily for mixing, kneading, and blending various materials. Usually, pug mills are associated with the ceramics and pottery industry, but their application extends to different industries as well.

Over the years, Stalwart International’s pug mill mixers have served numerous industries, especially the chemical, construction, and putty manufacturing industries, with a wide range of applications. Carefully designed pug mills help remove air pockets, mix ingredients evenly, and prepare the materials for shaping, forming, or extrusion.

WHAT WE OFFER

UNMATCHED EXCELLENCE AND RELIABILITY

CLIENTS' TESTIMONIALS

GOOD READS

Dynamic Blog