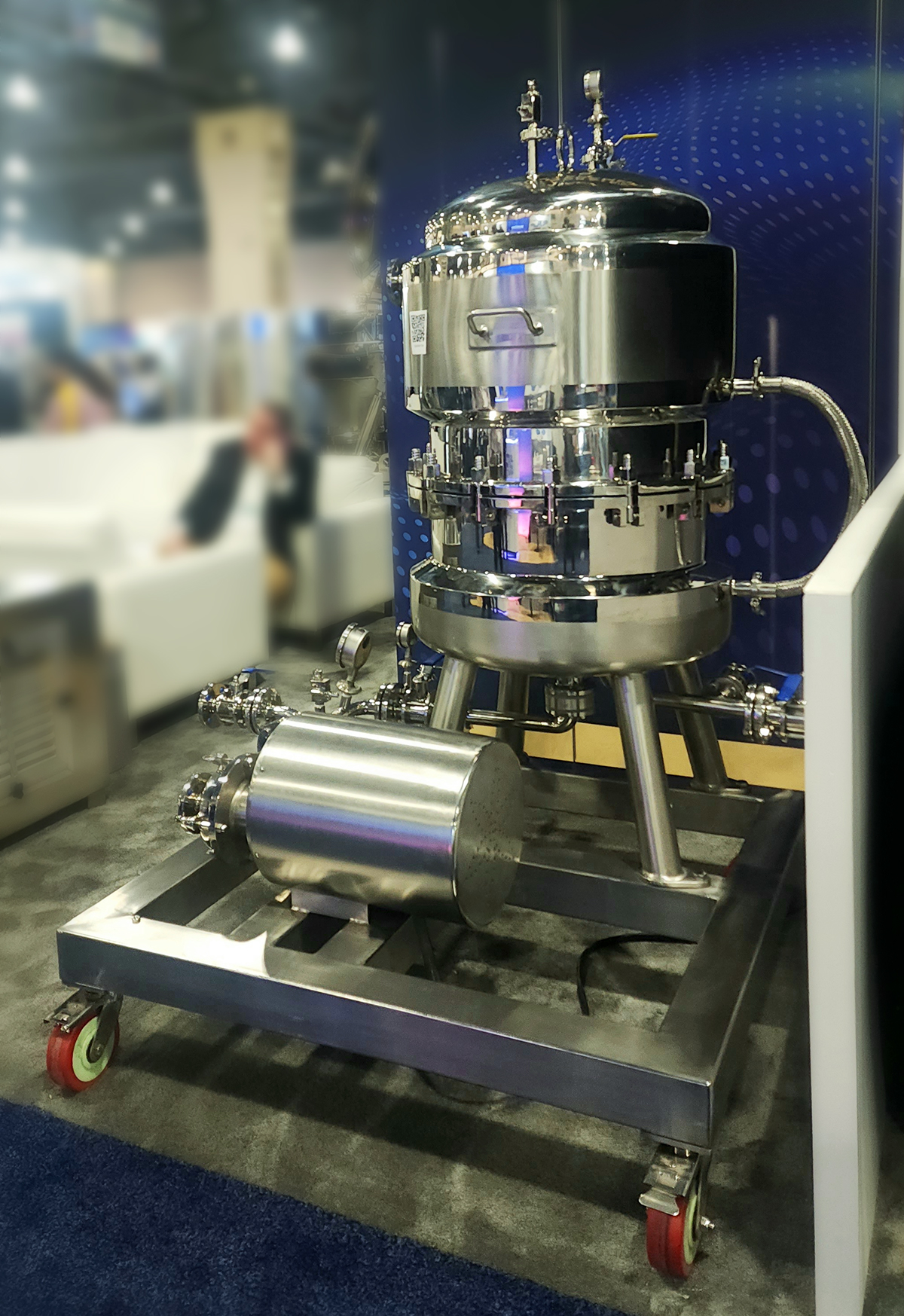

The Zero Hold Up Filter Press stands out for delivering top-tier filtration quality, ideal for high-value and hazardous liquids. Compliant with GMP and FDA norms, it is adaptable with various pumps such as Centrifugal, Gear, Lobe, and Roto, tailored to specific applications. The cartridge assembly features perforated screens, plates, spacers, and filter media, ensuring precise and efficient filtration.

The Zero Hold Up Filter Press is a crucial tool for industries needing high-quality, consistent filtration. Its innovative design and operational efficiency make it an indispensable asset for achieving contamination-free filtration.

- Single Pass Filtration: No solid bypass, ensuring complete batch recovery.

- Closed System: Safely filters toxic, hazardous, and explosive materials.

- Central Feeding: Guarantees no solids remain in the vessel, ensuring full liquid recovery.

- Easy Maintenance: Quick removal and cleaning of the cartridge assembly for efficient sterilization.

Preparation involves ensuring the filter press is clean and free from any residue. Confirm that the filter media is correctly sized and that the pump and pipelines are in good condition.

Charging the Filter Press starts by connecting the inlet pipeline to the pump and charging the filter press with the liquid to be filtered. The liquid fills the filter chambers, and the pump pressurizes it.

Filtration begins once the filter press is charged. The liquid flows through the filter media, trapping impurities and solids. The clean liquid then exits the filter press through the outlet pipeline.

Discharging the Filter Press occurs after the filtration process is complete. Switch off the pump and open the outlet valve to allow the filtered liquid to flow into a collection container.

Cleaning and Maintenance are crucial after using the Zero Hold Up Filter Press. This involves removing and cleaning the filter media, as well as cleaning the filter press chambers, pipelines, and pump. Regular maintenance ensures the filter press operates efficiently and prolongs its lifespan.

Exceptional Filtration Quality

- Achieves crystal-clear filtration for high-value liquids in industries such as pharmaceuticals, syrups, and beverages.

- Safe for toxic, hazardous, and explosive substances with its enclosed design.

Zero Hold Up Design

- Reverse liquid flow ensures zero hold up, facilitating complete batch filtration.

- Full batch recovery without needing a separate scavenging system, minimizing waste and solvent usage.

Versatility and Efficiency

- Suitable for chemical, distillery, beverage, ink, oil, pharmaceutical and allied industries.

- Supports a variety of filter media to achieve the desired micron efficiency.

- High flow rates and quality output enhance operational efficiency.

User-Friendly Operation

- Dome structure for quick cartridge removal and cleaning..

- Flexible plates adjust to varying toxicity levels.

- The cake can be dried using air or nitrogen, reducing solvent costs

The Zero Hold Up Filter Press is essential across diverse industries for its robust filtration capabilities. It efficiently filters acids, alkalis, solvents, and corrosive liquids in the chemical sector. In pharmaceuticals, it ensures purity in liquid medicines, antibiotics, and syrups. It clarifies beverages like wine, beer, and fruit juices, and purifies oils in food production. It also filters paints and varnishes in manufacturing, purifies water in treatment plants, and handles mining slurries and mine water. Its versatility and reliability make it indispensable for maintaining high filtration standards in industrial processes.

The Zero Hold Up Filter Press is a filtration system created to ensure filtration of liquids without retaining any unfiltered liquid. This ensure that all the liquid passes through the filter media preventing any product wastage.

WHAT WE OFFER

UNMATCHED EXCELLENCE AND RELIABILITY

CLIENTS' TESTIMONIALS

GOOD READS

Dynamic Blog